Vac-Ex T-VAC 2 Solves Rail Issues

Contamination of rail ballast, which is the material that forms the trackbed of railway lines is a significant problem that can affect the stability and safety of the track, as is replacing existing power and cable utilities. Previously this work was done using a skid-mounted system that has to travel on the rail which can cause disruption and inconvenience.

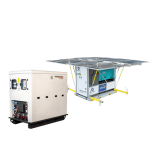

Ballast contamination can occur when fine particles like clay or silt accumulate beneath the ballast, leading to soft spots which create slurry or mud which results from poor drainage, heavy repetitive traffic loads and/or a subgrade weakness. A cost-effective answer to fixing these issues is the Vac-Ex T-VAC 2, a tracked air vacuum excavation unit that can easily fit alongside the rail tracks and undertake various inspection, identification and service work. Capable of excavating most types of wet or dry ground the Vac-Ex T-VAC 2 air vacuum excavator can access an array of sites where space is limited and can also used for pot holing.

Over the last 6 months Downer’s National Projects Division has been using the Vac-Ex T-VAC 2 for railway improvements as well as local street upgrades. It’s proven to be ideal in both instances as the unit is only 1.77m wide making it easier to access rail corridors and streets thereby reducing site congestion. It is also under 3.5ton so can comfortably and legally be towed on a trailer, behind a ute or placed on a rail car. The unit comes with an onboard compressor which is a twin-turbine suction system, robust enough for the removal of ballast into the bigger 1m3 hopper capacity.

“The Vac-Ex T-VAC 2 has saved us a huge amount on subcontractor costs and is great for getting to hard-to-reach places”, says Downer’s Nick Werner, Supervisor Rail and Civils, Infrastructure Delivery, Transport & Infrastructure. “We transport the Vac-Ex T-VAC 2 as close as possible to the site, offload it from the trailer, set it up and have it working 10 to 12 hours shifts on average. The good thing is that the machine is always there when you need it, there’s no wet spoil to dispose of and removed ballast can be dropped at the works location for reuse when suitable as it is not contaminated.”

According to Nick Werner the operators find the Vac-Ex T-VAC 2 simple to use and that they can plan their day without relying on subcontractors. Training sessions are conducted by YR to familiarise operators with the operating procedures of the Vac-Ex T-VAC 2. “The emphasis is on effective, efficient and safe practices,” says Nick. “Our operators have R, T and W (Rollers, Tracks and Wheels) licence endorsements so they have a real understanding of what it takes to use track laying vehicles, wherever the location.”